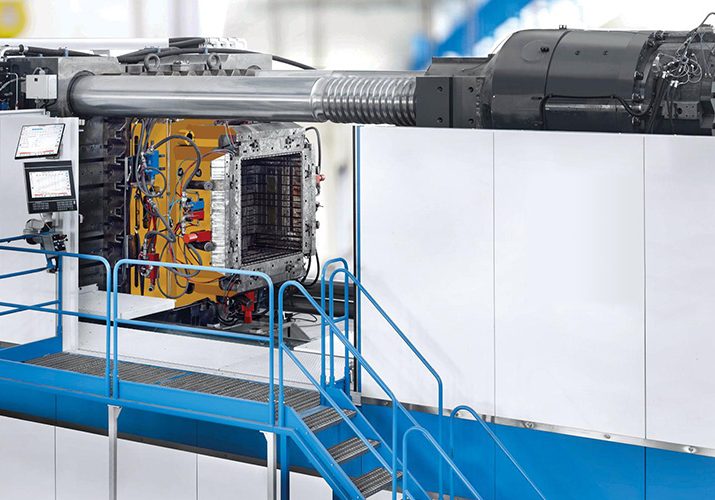

Supporting the plastics industry

The Polymer Machinery Manufacturers and Distributors Association (PMMDA) is a well-established trade organisation committed to advancing the plastics industry. We offer essential insights and reliable support, to help companies thrive, build connections, and achieve their goals. Become a member to gain access to valuable resources, expert guidance, and a community of professionals equally passionate about the industry.

Networking & social events

The focus of PMMDA’s activities remains in exchanging information through networking and social events; provision of market statistics and industry data; communication of regular business and industry updates; representation and feedback on the development of EU and ISO Standards; and negotiation of member advantage at exhibitions and events.

Meet the committee

Dave Raine

Director of Sumitomo

Demag (SHI) UK Ltd

Richard Hird

UK Sales Director of

Labotek GB Ltd

Matthew Ross

Sales Director

Summit Systems Ltd

Nick Fox

Managing Director of

Piovan UK Ltd

Michael Craig

Area Sales Manager

BMB UK Ltd

PMMDA Profile

Whilst the faces may have changed, the association’s main aims have never altered, and a commitment to the education of potential industry employees has been backed by our financial support of the Plastics Industry Awards to support students. A ‘Service Managers Group’ has recently been formed to support our member companies and the need for adherence to safety standards and health and safety regulations. This group meets regularly to discuss and compare company procedures including generic risk assessment and method statements.